U-SERIES

FOR MULTIPLE GRINDING OPERATIONS

Robot à la carte

- Multiple grinding operations in a single fixture

- Multiple workstations possible

- Full integration with existing production lines

- Easy programming

- Suitable for large work pieces

- Synchronous track (optional)

- Automatic tool- and motor change (optional)

INTEGRATION?

LARGE WORK PIECES?

U200!

highlights

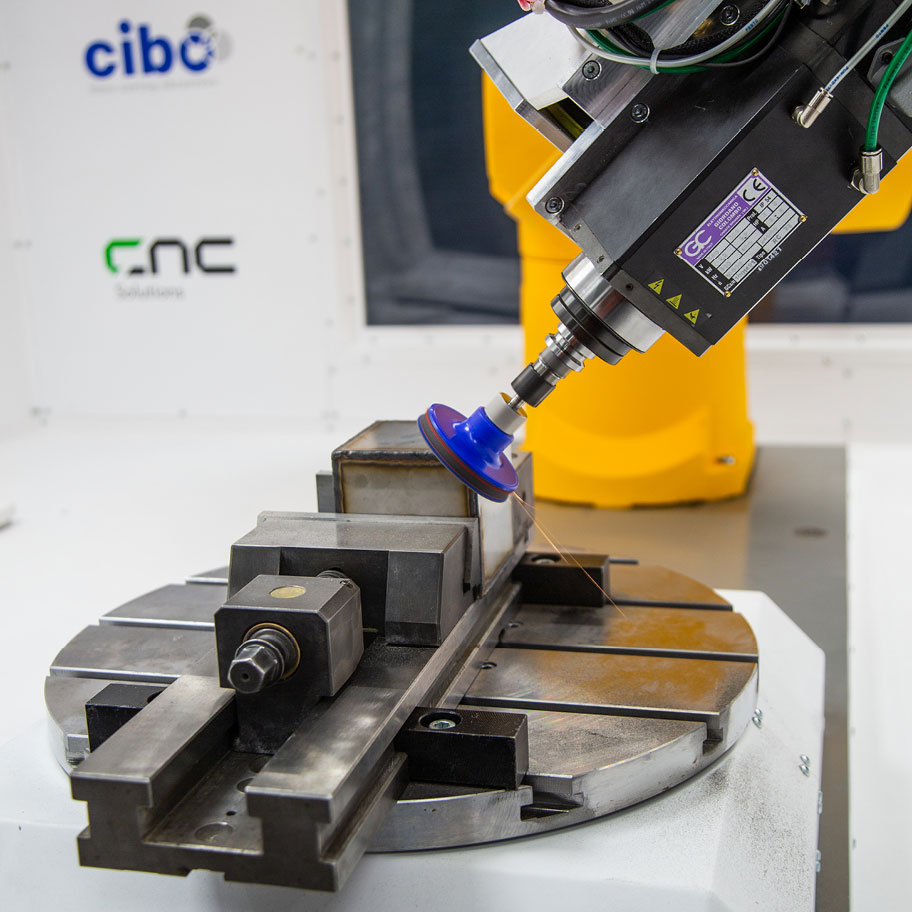

Compensator

You can use the compensator, mounted between robot and grinding motor, to ‘feel’ the work piece first before applying full grinding pressure.

synchronous turntable

The movements of the robot and the turntable can be perfectly tuned to each other, so a much greater range is possible.

touchscreen

The robot cell has an 18” touchscreen, with an overview of all process parameters displayed on the main screen.

hand held

You can start programs, operate the robot manually and adjust parameters using the hand-held controller.

tool change warehouse

The robot can automatically switch tools to perform different grinding steps one after the other.

Specifications

1. ROBOT

- Length of the robot arm: 2.000 mm.

- Lifting capacity: 100 kg nominal.

- Repeatability accuracy (ISO 9283): +/- 0.06 mm.

2. ELECTRIC CONTROL CABINET

-

18″ touch screen for operation.

-

Supplemented with integrated

control buttons.

3. ROBOT FOOT

-

Welded construction with space for electrical and pneumatic components.

-

Milled top surface with recess for the connections of the robot.

4. GRINDING MACHINE

-

Quick tool changer

(mechanical tool change system). -

2.2 kW at 18,000 rpm, maximum speed: 24,000 rpm.

-

HSK 32C take up.

5. OPERATION

-

Constructed as a CNC control with simple operation.

-

The main screen displays an overview of all process parameters.

-

Possibility to run different programs one after the other.

-

Possibility to work with different set points.

-

Integrated tool table.

-

Audit and IO review.

-

The robot can be easily operated manually if required.

-

Possibility to open CNC files from different carriers.

1. ROBOT

- Length of the robot arm: 1.600 mm.

- Lifting capacity: 20 kg nominal.

- Repeatability accuracy (ISO 9283): +/- 0,05 mm.

2. ELECTRIC CONTROL CABINET

-

18″ touch screen for operation.

-

Supplemented with integrated

control buttons.

3. ROBOT FOOT

-

Welded construction with space for electrical and pneumatic components.

-

Milled top surface with recess for the connections of the robot.

4. GRINDING MACHINE

-

Quick tool changer

(mechanical tool change system). -

2.2 kW at 18,000 rpm, maximum speed: 24,000 rpm.

-

HSK 32C take up.

5. OPERATION

-

Constructed as a CNC control with simple operation.

-

The main screen displays an overview of all process parameters.

-

Possibility to run different programs one after the other.

-

Possibility to work with different set points.

-

Integrated tool table.

-

Audit and IO review.

-

The robot can be easily operated manually if required.

-

Possibility to open CNC files from different carriers.

1. ROBOT

- Length of the robot arm: 1.000 mm.

- Lifting capacity: 14 kg nominaal.

- Repeatability accuracy (ISO 9283): +/- 0,03 mm.

2. ELECTRIC CONTROL CABINET

-

18″ touch screen for operation.

-

Supplemented with integrated

control buttons.

3. ROBOT FOOT

-

Welded construction with space for electrical and pneumatic components.

-

Milled top surface with recess for the connections of the robot.

4. GRINDING MACHINE

-

Quick tool changer

(mechanical tool change system). -

2.2 kW at 18,000 rpm, maximum speed: 24,000 rpm.

-

HSK 32C take up.

5. OPERATION

-

Constructed as a CNC control with simple operation.

-

The main screen displays an overview of all process parameters.

-

Possibility to run different programs one after the other.

-

Possibility to work with different set points.

-

Integrated tool table.

-

Audit and IO review.

-

The robot can be easily operated manually if required.

-

Possibility to open CNC files from different carriers.

ROBOT IN ACTION

Smoothing welded joints on metal office furniture.

Deburring punching burrs on truck handles.

Grinding and polishing stainless steel pump housings.

Interested in this robot?

Contact one of our grinding specialists!

COMPARE

| Robot cell with cabin | Robot cell with cabin | Robot à la carte |

| Single grinding operation in a single fixture | Multiple grinding operations in a single fixture | Multiple grinding operations in a single fixture |

| Easy programming | Easy programming | Easy programming |

| SprutCam software | SprutCam software | SprutCam software |

| Compact device |

Automatische tool- en schuurmaterialen wissel (optioneel) Synchronous turntable (optional) |

Multiple workstations possible Synchronous track (optional) |

| Suitable for smaller work pieces | Suitable for medium work pieces | Suitable for large work pieces |

| Operational in a few hours | Operational in 1 day | Operational in a few days |

COMPARE

E-SERIES |

S-SERIES |

U-SERIES |

| Robot cell with cabin | Robot cell with cabin | Robot à la carte |

| Single grinding operation in a single fixture | Multiple grinding operations in a single fixture | Multiple grinding operations in a single fixture |

| Easy programming | Easy programming | Easy programming |

| SprutCam software | SprutCam software | SprutCam software |

| Compact device |

Automatische tool- en schuurmaterialen wissel (optioneel) Synchronous turntable (optional) |

Multiple workstations possible Synchronous track (optional) |

| Suitable for smaller work pieces | Suitable for medium work pieces | Suitable for large work pieces |

| Operational in a few hours | Operational in 1 day | Operational in a few days |